▲

Sprawność przewodzenia ciepła | ◎ | ▲ | Wygoda obsługi | ◎ | ▲ | Wydajność przetwarzania | ◎ | ◯ |

| Czystość | ◎ | ▲ | Odporność na ciepło | ◎ | ◯ | Recykling i ponowne wykorzystanie | ◯ | ◎ |

| Odporność na wilgoć | ◎ | ▲ | Opłacalny | ◎ | ▲ | ◎: | Doskonały | ◯ |

| :Dobry ▲:Słaby | 6. Oszczędności kosztów | Nasza firma, biorąc pod uwagę aktualną sytuację klientów, opracowała program oszczędnościowy, który może pozwolić na oszczędność kosztów rzędu 10-20% w porównaniu z tradycyjnym papierem typu kraft, zgodnie z danymi obecnej bazy klientów. | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

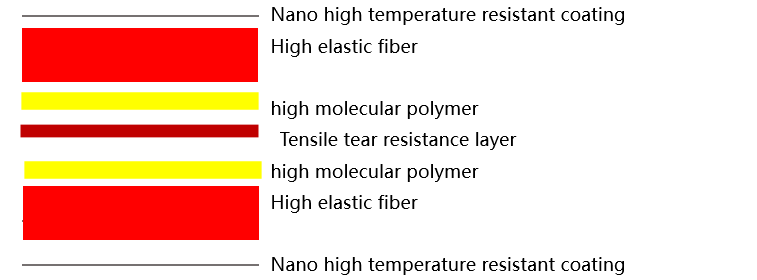

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the equal pressing process of PCB and IC carrier board. It has good thermal conductivity and can solve the problem of lack of glue such as thick copper and low residual copper rate.

1. Independent Research and Development

Our commitment to in-house R&D ensures continuous innovation and customization capabilities. By leveraging cutting-edge technologies and material science expertise, we develop solutions tailored to specific industrial challenges—such as creating buffer pads that withstand extreme temperatures (up to 260°C) and pressure. This autonomy allows us to rapidly prototype and refine products, ensuring they meet the highest standards of durability, thermal stability, and performance.

2. Independent Production

Full control over our manufacturing processes guarantees unmatched quality and consistency. By vertically integrating production, we eliminate reliance on third-party suppliers, reducing risks like supply chain delays or material inconsistencies. Our state-of-the-art facilities utilize advanced automation and precision engineering, ensuring every product—from high-temperature-resistant pads to flame-retardant solutions—adheres to strict specifications.

3. Short Production Cycle

Optimized workflows and agile manufacturing enable us to deliver products swiftly, with lead times reduced by up to 30% compared to industry averages. This efficiency is critical for industries like lithium battery manufacturing or PCB production, where rapid turnaround times are essential for meeting tight project deadlines or adapting to market demands.

4. Faster Technical Services

Our dedicated technical support team provides immediate, expert assistance—whether for troubleshooting, process optimization, or customization requests. With an average response time of under 4 hours, we ensure minimal downtime for clients. For example, our engineers recently helped a customer integrate our buffer pads into a high-pressure pressing system, resolving thermal uniformity issues within a single production cycle.

Synergistic Advantages

Together, these capabilities position us as a leader in high-performance industrial solutions. By combining bespoke R&D, rigorous production control, rapid delivery, and responsive support, we empower industries like CCL, PCB, and energy storage to achieve higher efficiency, lower costs, and enhanced operational reliability. Our end-to-end control over innovation and execution ensures that every product not only meets but exceeds the evolving demands of modern manufacturing.

| Compare Item 1 | Navies pad | Bullskin paper | Compare Item 2 | Navies pad | Bullskin paper |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

According to the actual situation of customers, our company formulates a cost saving scheme, which can save 10-20 % cost compared with conventional kraft paper according to the current customer base.

Zapewnienie jakości usług: Upewnij się, że dostawcy usług mają profesjonalne umiejętności i dobre nastawienie, aby świadczyć usługi wysokiej jakości. Terminowa reakcja i rozwiązywanie problemów, w przypadku problemów i potrzeb klientów personel wsparcia serwisowego powinien reagować w odpowiednim czasie i podawać skuteczne rozwiązania.

Więcej